Aiming at the problems existing in the power supply system of the mine, 1140V mining flame-proof and intrinsically safe static var generator (SVG for short) came into being. The product is a reactive compensation system with IGBT as the core, which can provide capacitive or inductive reactive power quickly and continuously. Advanced instantaneous reactive power theory and power decoupling algorithm based on synchronous coordinate transformation are adopted to operate with the setting reactive power property and size, power factor, power grid voltage and other control targets, the change of grid power quality is dynamically tracked to adjust reactive output, and the curve setting operation is realized. It can improve power factor, balance three-phase voltage, inhibit voltage flicker and voltage fluctuation, control harmonic pollution, etc., and the power quality problems existing in underground power supply system can be solved completely.

The heat dissipation of the whole machine adopts advanced water-water cooling technology and deionized water circulation cooling system, so it has high heat dissipation efficiency, high reliability, low noise and longer service life of the equipment.

Film capacitor is adopted in the unit, so it has good thermal stability and long service life.

Dynamic response speed is fast, and the response time ≤ 5 ms.

The ttal harmonic current distortion (THDi)≤3%.

A variety of operation modes can meet the needs of users greatly. The operation modes include: constant device reactive power mode, constant check point reactive power mode, constant check point power factor mode, constant check point voltage mode and load compensation mode. The target value can be changed in real time.

Real-time tracking of load changes, dynamic continuous and smooth compensation of reactive power, improvement of system power factor, real-time harmonics control, filtering out 5.7.11.13 harmonics, compensation of negative sequence current, improvement of power supply quality of power grid, and guarantee of normal operation of equipment.

Restrain voltage flicker, improve voltage quality and stabilize system voltage.

The protection function is complete, with over-voltage, over-current, unit overheating, uneven voltage protection, and can realize waveform recording at the moment of failure, so it is convenient to determine the failure point, easy to maintain and high in operation reliability.

Save energy and reduce consumption, and improve the utilization rate of the equiment to electrical energy.

The equipment has a compact structure, modular design, small floor area and convenient movement.

Product model | Mining flame-proof and intrinsically safe static var generator |

Product function | Improve power factor, control harmonics, balance three-phase voltage, and suppress voltage flicker and voltage fluctuation |

Rated voltage | AC 1140V |

Rated capacity | ±500kvar |

System frequency | 50Hz |

Performance Indexes |

Overload capacity | 120%/1min |

Response time | ≤5ms |

Active loss | ≤0.8% |

Total harmonic current distortion (THDi) | ≤3% |

Reactive power regulation mode | Capacitive and inductive automatic continuous smooth adjustment |

Starting power | 5kvar |

Compensation current resolution | 0.5A |

Operation mode

| Reactive power mode of constant device, constant check point reactive power mode, constant check point power factor mode, constant check point voltage mode, load compensation mode, time-sharing 96-point control |

Display and Interface |

Display specifications | 7' all-Chinese man-machine interface |

Communication interface | Communication interfaces such as RS485 and CAN, and high-speed optical fiber communication interface |

Communication protocol | Standard MODBUS_RTU Communication protocols such as optional ProfiBUS, power CDT91 protocol, IEC61850-103/104, CANOPEN protocol and user-defined protocol (it can be freely set on the touch screen) |

Protection function |

Protection function | Over-voltage of busbar, over-temperature of power unit, system overload, system short circuit, system over-voltage, abnormal protection of system frequency, abnormal power of external fault protection system, etc. |

Cooling Method, Level of Protection, Size and Weight |

Cooling mode | Water cooling heat dissipation |

Level of protection | IP54,Ex d [ib] I Mb |

Overall dimensions

|

2200mm*14490mm*1320mm

|

重量

Weight | 13000kg |

Environment conditions |

Environment conditions | Meet the requirements of GB3836.1 |

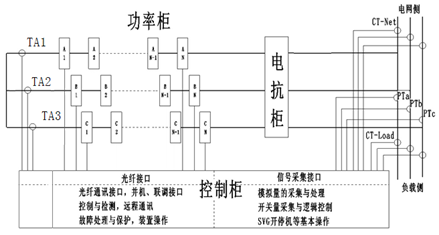

WJL explosion-proof products are installed in the flame-proof chamber. The internal structure is mainly divided into four parts: control cabinet, power cabinet, reactor cabinet and water cooling system.

1、Control cabinet

Main components: main control box, PLC, man-machine interface, switching power supply, filter, self-developed uninterruptible power supply system, etc.

Main functions: including HMI, PLC, ARM, FPGA, DSP and other high-precision chips, and adding carefully designed algorithms to ensure the best operation performance of explosion-proof SVG. The self-developed main control box has passed strict EMC (electromagnetic compatibility) certification, and has been processed through temperature cycling and vibration test. It has extremely high reliability, friendly human-machine interface display, explosion-proof and dust-proof mouse operation, so the free control of equipment startup and shutdown operations is realized.

2、Water cooling system

Main components: main circulating pump, filter, pipeline, cooling medium, etc

Main function: the cooling medium is boosted by the main circulating pump and then flows through the plate heat exchanger. After being cooled, the cooling medium enters the power device to carry out the heat and then returns to the main circulating pump for closed reciprocating circulation.

3、Mine cable connector

Main function: connect the primary cable input, with high insulation, quick connection and convenient operation.

4、Reactance cabinet

Main components: water-cooling reactor, AC contactor, transformer

Main function: connect to power grid through reactor, better sine degree of current waveform; The reactor also suppresses SVG harmonics when smoothing. The AC contactor is used for turning on/off the main loop. The transformer provides power for the system.

5、Power cabinet

Main components: water-cooling power unit, current sensor

Main function: the power unit is installed in three phases, with equal number of units in each phase; each unit can realize SPWM control through IGBT inverter bridge, water cooling heat dissipation is adopted, so it has high heat dissipation efficiency, and improves the service life of equipment. The optical fiber communication technology is adopted between the controller and the power unit, and the low-voltage part.