Products

G7 All-in-One Inverter

Based on two-quadrant synchronous (including permanent magnetic synchronous motor)/asynchronous motor platform, this series has its control-gear, power cabinet, transformer cabinet and switchgear integrated for easy installation. Small size saves space; overall transportation ensures easy installation

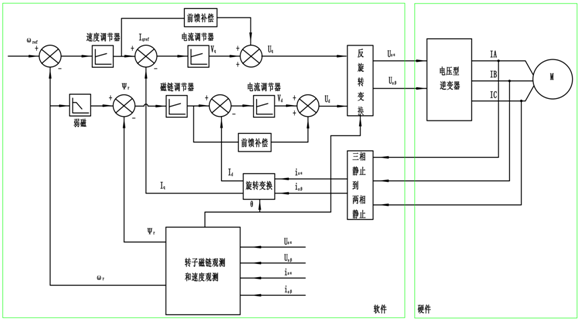

1、Vector control, fast response

The current vector of AC motor’s stator is measured and controlled to control the exciting current and torque current of the AC motor under field orientation principle, thereby controlling AC motor’s torque. The faster the starting quarter, the faster the torque dynamic response, the higher the speed regulation and the higher the loading capacity. Asynchronous and synchronous motors can be driven.

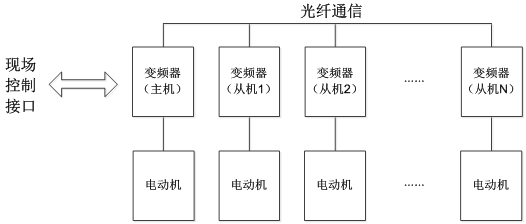

2、Multi-machine linkage, power balance

The inverter provides master/salve control function. Multiple inverter can form a master/slave control network through data buses with one of them as the master and other salves. The master connects the real-time states of salves and send frequency and torque commands to slaves, a way that balances powers and provides comprehensive control of all inverter. This control technology is suitable to applications that require balanced power, such as belt conveyor and friction hoist.

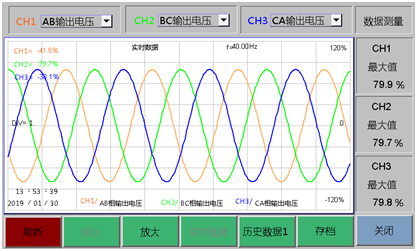

3、Waveform Display and Analysis

Main control system monitors input current, input voltage, output voltage and output current and displays their waveforms in a real-time manner, and also performs harmonics analysis for the voltage and current of each phase, a way that helps users get electrical parameters of the device.

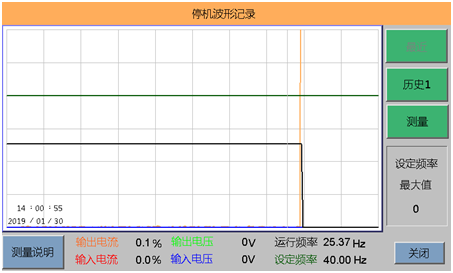

4、Black Box

The inverter is able to record operating state and display data automatically, through which, output voltage, output current, preset frequency, operating frequency, input current and input voltage at 200 points (100 ms) can be checked, easy for daily maintenance.

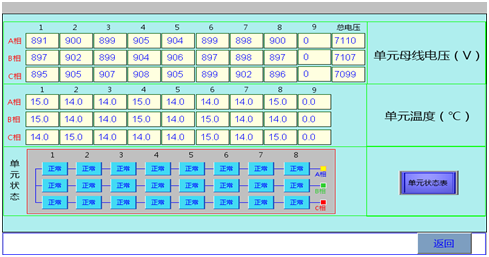

5、Unit Temperature Alarm

Main control system monitors and displays each power unit’s temperature in a real-time manner. When two or more units exceed the preset warning temperature, a combined optical and audible alarm will be sent to the user who will then time settle problems that cause the over-temperature, such as air blower trip or blocked filter.

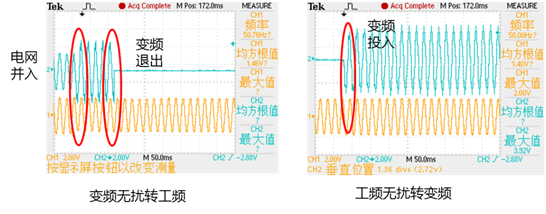

6、Easy Industrial/Variable Frequency Switching

Variable frequency to industrial frequency: The inverter drives the motor to industrial frequency and adjusts its own output voltage by detecting the frequency, phase and amplitude of industrial frequency grid. After that, the motor is detached from inverter and connected to grid. Industrial frequency to variable frequency: After the motor is detached from grid and connected to inverter, inverter directly outputs voltage vector by detecting frequency, phase and amplitude of industrial frequency grid. This technology can satisfy the requirements for comprehensive motor control and soft-starting of large-capacity motors.

7、High/low Voltage Ride Through,No fear of fluctuation

If the main power source fails or dips abruptly or the industrial power grid is switched, the inverter is able to continue operating within a certain time after the grid recovery by its high/low voltage ride through technology that increases grid adaptability.

8、Other Technical Information

Dual Power Supply Circuit:Secondary coil of the transformer is used as a backup control power supply to ensure safety when the system is operating.

High Power Density:Small unit volume and modularized design; compact device that requires a small space.

DC Injection Braking:When the motor is rotating (10Hz or lower frequency), direct current is injected for braking to change the motor from rotation to stop.

Current Limiter:If the current exceeds the preset limit when the VFD is operating, the current can be decreased by lowering frequency until it is lower than the preset limit; then, the normal operating frequency will be recovered.

Over-Voltage Stall Protection:The VFD can increase extend the frequency lowering time if the motor generates electricity or the bus voltage is increased during the frequency lowering period, in order to prevent stall caused by bus over-voltage.

Multiple controls:Multiple controls are available, including local control, remote box control and DCS control, supporting MODBUS, PROFIBUS and other communication protocols. Frequency can be set either locally or through communication. Frequency presetting and acceleration/deceleration are supported.

Adaptive Acceleration/Deceleration :The VFD adjusts acceleration time or limits motor’s operating frequency given motor’s load current in order to limit the current, protecting against over-current during acceleration. The VFD adjusts the frequency lowering time given the bus voltage to protect against over-voltage during frequency lowering.