Solution

The Application of SVG Chain Reactive Power Compensation Device in Electric Arc Furnace

1 Introduction

A notice on firmly curbing newly launched iron, steel and coal production projects in breach of regulations, cracking down substandard steel products and building a good production and operation environment was printed and distributed by the government in December, 2016. The substandard steel mentioned in this notice refers to steel made from crap steel products which are melted in induction furnaces, a way that cannot effectively control the steel composition and quality. The substandard steel, mainly produced in middle-frequency furnaces, is primarily used for building purpose and considered highly risky in quality.

The Guangdong steel factory provides integrated steel production that covers steel melting and forging, with a specification on rebar production. At the beginning of 2017, in order to improve steel quality, it transformed middle-frequency furnaces to electric arc furnaces, which, after put into service, caused 35 kV grid voltage fluctuation and huge voltage flicker that was much higher than specified threshold, an accident that resulted in the failure of an adjacent water power station.

Electric arc furnaces are simply structured but impose significant impacts on grid voltage. During melting period of an electric arc furnace, materials are not completely melted, arcs are instable, resulting in frequent arc interruptions and restrikes, and even short circuits between electrodes. At the beginning of melting period, current waveform is irregular, with a large harmonic component mainly consisting of low –order harmonics, and sometimes, the current containing harmonics accounts for 20% of the total current. In the same period, negative sequence component accounts for a large share of the unbalanced three-phase current; when the arch extinguishes in a phase and the other two phase become short circuit, negative sequence component of the fundamental current wave reaches its peak. The most serious problem encountered by electric arc furnaces is not harmonics but voltage fluctuation and flicker, a problem that may hugely impact the safety of grid and other electricity consumption equipment.

2 Electricity Consumption of Electric Arc Furnace and Its Compensation Requirements

2.1 Primary Electricity Distribution Diagram

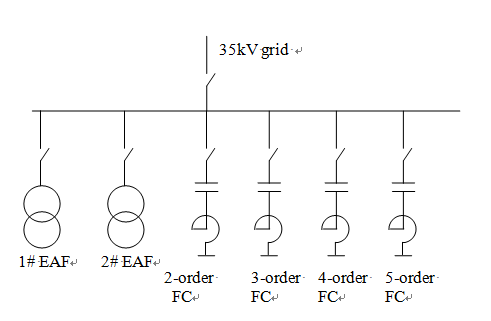

The primary electricity distribution in the Guangdong steel factory is indicated in Figure 1.

Figure 1 Primary Electricity Distribution Diagram

2.2 Loads

Loads in the project are listed in Table 1.

Table 1. List of Loads

Load Name | Voltage Level | Rated Power | Qty | Load Type | Remarks |

1# EAF | 35kV | 16000kVA | 1 | Inductive | Impulse |

2# EAF | 35kV | 16000kVA | 1 | Inductive | Impulse |

While upgrading middle-frequency furnaces to electric arc furnaces, the steel factory has also installed FC compensation devices as shown in Table 2.

Table 2 FC Compensation Devices

Load Name |

Voltage Level | Installed Capacity | Fundamental Wave Capacity | Tuning Order | Filter Type |

2次FC 2-order FC | 35kV | 4100kvar | 2500kvar | 2 | Single tuned |

3次FC 3-order FC | 35kV | 5400kvar | 4000kvar | 3 | Single tuned |

4次FC 4-order FC | 35kV | 3100kvar | 2200kvar | 4 | Single tuned |

5次FC 5-order FC | 35kV | 5000kvar | 3500kvar | 5 | Single tuned |

2.3 Electricity quality problems in this project

The fast reactive power impulse generated by electric arc furnaces, despite of the installation of FC compensation devices whose capacity is far from enough, could be properly solved. Grid voltage flicker exceeded the standard. Unstable grid voltage resulted in the failure of the adjacent water power station where generation unit vibrates violently with volatile reactive current and active current. In addition, when load of the electric arc furnaces was lowered, system side received excessive compensation.

To lower the investment, the factory owner only required no disruption to the production of surrounding enterprises by increasing the power factor to higher than 0.9.

2.4 Compensation solution for this project

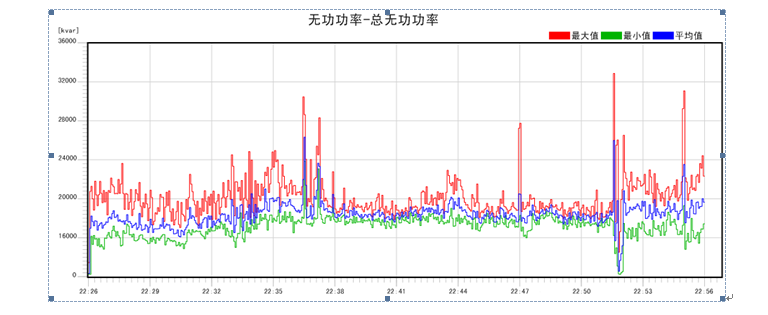

A proper compensation capacity was designed by considering electricity quality and user requirements. Test result indicated that maximum reactive impact from an electric arc furnace could be more than 2 times of its VFD, as shown in Figure 2.

Figure 2 EAF Reactive Power Curves

In consideration of cost and on-site conditions, the compensation solution proposed by WindSun was to add one 35 kv direct mounted FGSVG whose capacity is 12.5 Mvar in addition to the existing FCs.

3 Basic Principle of WindSun SVG

SVG is the cutting-edge device for reactive power compensation both recognized in China and abroad. This voltage PWM converter-based compensation device has fundamentally improved reactive power technology. Instead of utilizing large capacity capacitors or inductors, it transforms reactive energy through high-frequency switching of electric and electronic components. The basic principle is to parallel a self-commutated bridge circuit into the grid through a reactor, and enables the bridge to absorb or generates required reactive current by adjusting the amplitude and phase of AC output voltage of the bridge or directly controlling its AC current, a way that can provides reactive power compensation. SVGs can provide fast current response and strong suppression of voltage flicker.

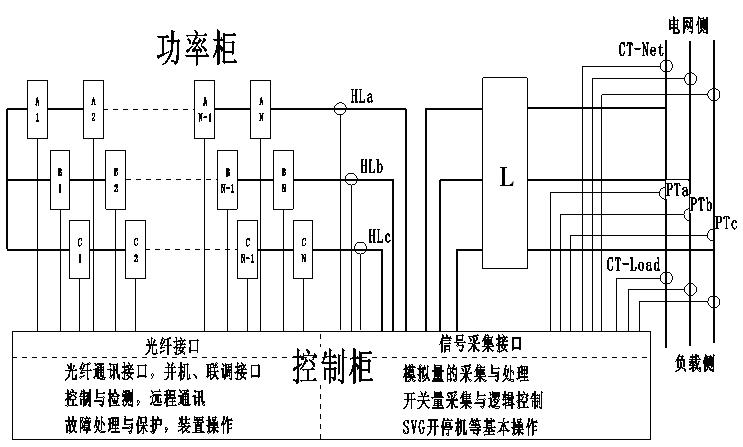

Figure 3 FGSVG Structure Diagram

WindSun 35 kV direct mounting SVG’s structure diagram is shown in Figure 3. The main circuit is a chained series. Each phase consists of several identical power units and each power unit is a bridge circuit formed by many high power electric and electronic components. Unit series and carrier phase shifting technologies make the output voltage more approximate to a sine waveform, avoiding many problems caused by high du/dt.

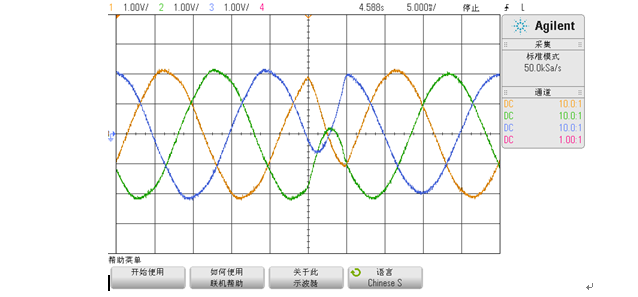

Imported electric and electronic modules are utilized as main power components for FGSVG products. Many DSPs and FPGAs form a powerful control system. Instantaneous reactive power theory-based control algorithm can fast and accurately identify reactive power of the system/load. To obtain faster response and higher performance, direct current control and carrier phase shifting are used, a combination that can fast control the reactive current after grid connection and provide better waveform after grid connection, as shown in Figure 4. FGSVG can continuously and fast provide capacitive or inductive reactive power to properly control voltage and reactive power, ensuring the stability, efficiency and quality of the electric system.

Figure 4 Waveform vs Time from Inductive Rated Current to Capacitive Rated Current

The power unit used in FGSVG is designed with redundancies for high reliability and based on the modular-concept which ensures high integration and good interchangeability. These guarantee easy installation and maintenance. In terms of size, it is only 50% of a conventional SVC with the same capacity. Many FGSVGs can be paralleled for easy capacity extension. High speed fiber optic cables used for parallel operation ensures high speed communication, meeting the fast compensation requirement. In addition, on-site operations are fairly easy. Super-large touch panel provides diverse pages for displaying for example, real time state quantities and analog quantities, historical operation events, history curves, unit states, system information and history failures, as well as special features like system self-test once the power supply is connected, one-key start/stop, time shared control, waveform recording by an oscilloscope (AD waveform recording), failure voltage/current waveform recording, etc.

4 Compensation Effect

The FGSVG is connected to a 35kV grid via a high voltage distribution cabinet and detects the grid voltage and current of 35kV system through a PT and CT for automatic compensation. FGSVG’s ability to identify PT and CT automatically makes its main controller to automatically analyze PT and CT wirings after the distribution cabinet is switched on. Having identified the phase sequences of PC and CT, it can be directly started to provide compensation. There are many automatic compensation modes available, i.e., targeted point reactive power mode, targeted point power factor mode, targeted point voltage mode, load compensation mode and comprehensive compensation mode.

With the FGSVG connected to the grid, in order to help remotely motor SVG operating data, user’s original computer used for monitoring purpose is connected to the external communication port of SVG through a twisted pair. FGSVG has many communication ports, such as RS-485, Ethernet port, and supports many conventional protocols in electricity industry, such as MODBUS_RTU, CT91 and IEC104. With these ports and protocols, online communication between the FGSVG and its background system is possible. In production, what operators need to do is regular patrol and cleaning, with very simple operation and maintenance. FGSVG that is working on the site is shown in Figure 5.

Figure 5 FGSVG Operating on the Site

4.2 补偿效果

4.2 Compensation Effect

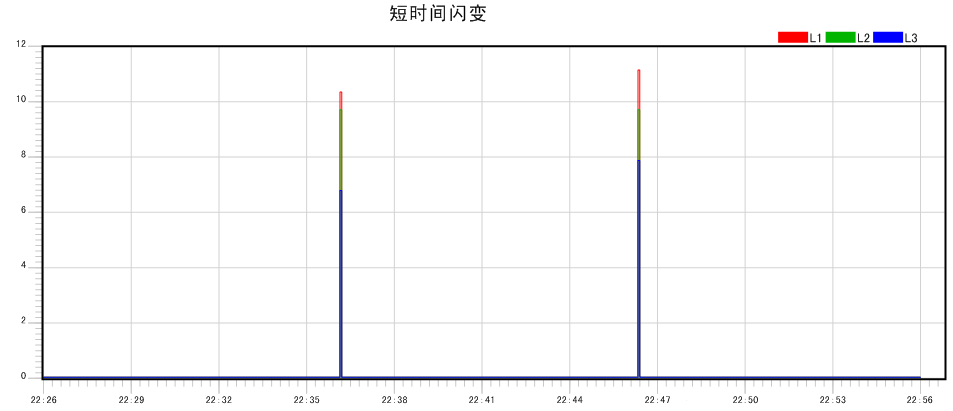

Before SVG was put into service, the short-time voltage flicker reached about 11.0, as indicated in Figure6

Figure 6 Short-term Flicker before SVG was Put into Service

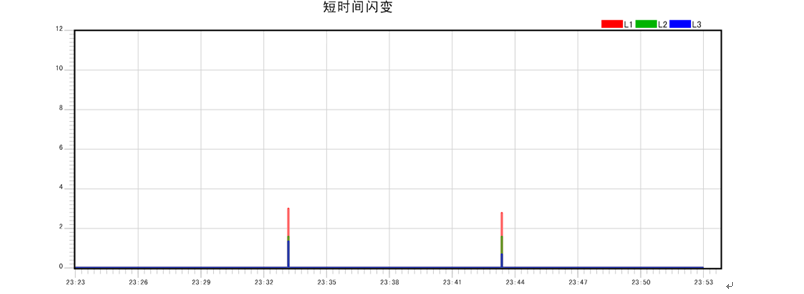

FGSVG, having been put into service, greatly suppressed grid voltage flicker, with the measured maximum flicker declined to about 3.0, as shown in Figure 7. The grid voltage fluctuation was significantly reduced. The generation unit in the adjacent water power station have not encountered the previous violent vibration, with a stable reactive current and slightly fluctuating active current, which does not affect normal production.

Figure 7 Short-time Flicker after SVG was put into Service

5 Conclusion

Electric arc furnaces are among equipment that bring about the highest risk to grid electricity quality in metallurgy. The operation of an electric arc furnace causes high harmonics, negative sequence and flicker, of which, flicker results in the largest damage whose extent is closely associated with the furnace’s capacity and grid capacity. In order to lower investment cost, the Guangdong steel factory used a smaller compensation capacity. Nevertheless, use of the high voltage dynamic reactive power compensation device (FGSVG) from WindSun Science & Technology Co., Ltd. has greatly decreased the grid voltage flicker, which not only eliminated the damage to the nearby water power station, but also enhanced the monthly average power factor in the steel factory to more than 0.96.