Products

PMSM Controller

With high speed DSPs as the core, Permanent Magnet Synchronous high-voltage VFDs are designed with space vector, multi-level power unit series and other advanced control technologies to be highly reliable, easily operated, highly functional and small in size for regulating speeds of various loads and improving production process. These are high-high voltage source VFDs, with harmonics much lower than the standard specified in IEEEE 519-2014. High input power factor and good output waveform save the use of input harmonic filter, power factor compensation device and output filter. They are free from problems caused by harmonics, e.g. additional heating and torque pulse, noise, common mode voltage and so on, and are suitable to two/four quadrant synchronous motors (including permanent magnetic synchronous motors) and asynchronous motors.

1、Powerful motor parameter self-learning

The permanent magnet synchronous high-voltage inverter can accurately identify parameters such as the stator resistance Rs of the permanent magnet synchronous motor, the straight-axis inductance Ld, the quadrature-axis inductance Lq, and the rated back-EMF of the motor. After the identification is completed, the data is recorded in the EEPROM, and it is not necessary to identify it again later. The motor parameters can be used for precise vector control of the motor.

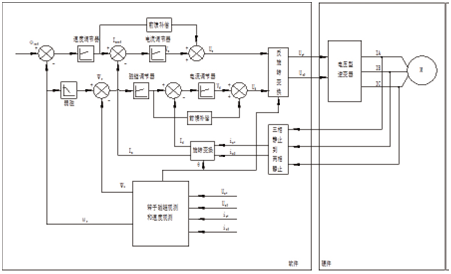

2、Vector control

The current vector of AC motor’s stator is measured and controlled to control the exciting current and torque current of the AC motor under field orientation principle, thereby controlling AC motor’s torque. The faster the starting quarter, the faster the torque dynamic response, the higher the speed regulation and the higher the loading capacity. Asynchronous and synchronous motors can be driven.

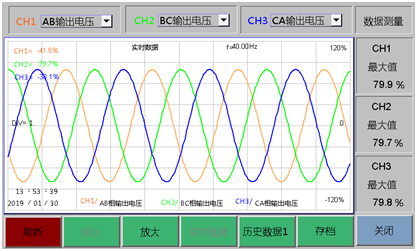

3、Waveform Display and Analysis

Main control system monitors input current, input voltage, output voltage and output current and displays their waveforms in a real-time manner, and also performs harmonics analysis for the voltage and current of each phase, a way that helps users get electrical parameters of the device.

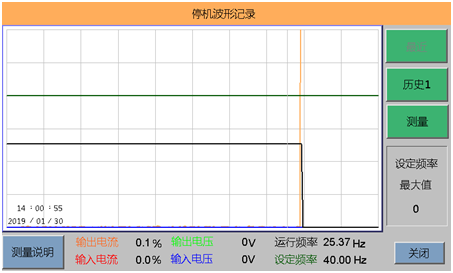

4、Black Box

The inverter is able to record operating state and display data automatically, through which, output voltage, output current, preset frequency, operating frequency, input current and input voltage at 200 points (100 ms) can be checked, easy for daily maintenance.

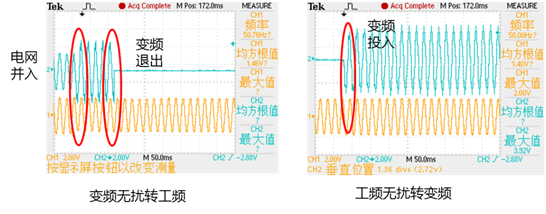

5、Easy Industrial/Variable Frequency Switching

Variable frequency to industrial frequency: The VFD drives the motor to industrial frequency and adjusts its own output voltage by detecting the frequency, phase and amplitude of industrial frequency grid. After that, the motor is detached from VFD and connected to grid. Industrial frequency to variable frequency: After the motor is detached from grid and connected to VFD, VFD directly outputs voltage vector by detecting frequency, phase and amplitude of industrial frequency grid. This technology can satisfy the requirements for comprehensive motor control and soft-starting of large-capacity motors.